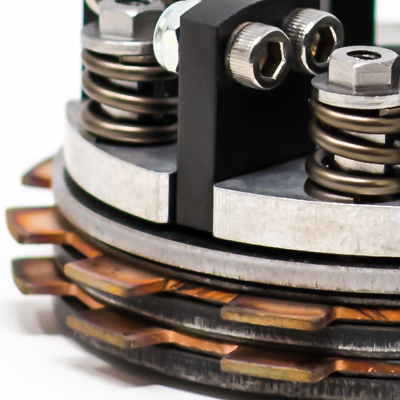

Aggressor 6×6 Clutches

Aggressor 6×6 clutches use compression springs connected to the pressure plate.

Advantages:

- The spring material accommodates higher temperatures; consequently, springs last much longer.

- The six compression springs are factory-matched for uniform pressure which minimizes chatter and eliminates the cost of “blueprinting”.

- The springs are accurately adjusted without a depth micrometer. Saves time and aggravation.

- The adjustment screws have “stops” to prevent coil bind and spring damage.

- The levers have fixed pins. Levers remain centered in their slots when the clutch is spinning.

- Friction material and plate surface finish are factory optimized for best performance. DO NOT BLUEPRINT.

- Discs can be easily removed and cleaned without disassembling the springs, levers and pressure plate. (Clean discs are faster.)

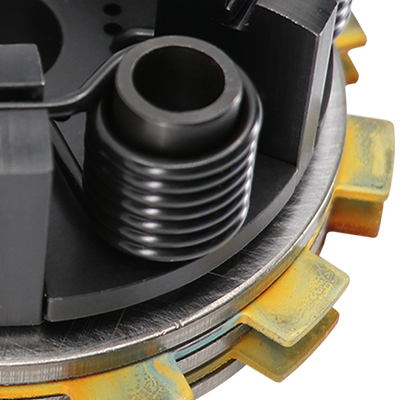

Vortex Clutches

Vortex clutches use torsion springs connected to the levers.

Advantages:

- Vortex clutches react more quickly to engine “bogging” improves acceleration.

- Torsion springs are simple and fast to adjust.

- Torsion springs do not use height measurements.

- Torsion springs are exceptionally less sensitive to air-gap. More laps before replacing discs.

- Vortex clutches lockup very smoothly.

Configurations:

- Vortex Clutches come in one, two, or three-disc variations.

- The hub bore (crankshaft diameter) is ¾ inch only.

- #35, #219 sprockets and 8mm pulleys are available.

- The sprockets employ a ball bearing, needle bearing, or bronze bushing depending on sprocket style, and tooth count.

- All pulleys use double-row ball bearings.

- Sprockets and pulleys are sold separately.